PRODUCT RANGE

LEAN MANUFACTURING

Vora Group has embraced Lean Six Sigma methodology as an integral part of our business model. We seek to improve the quality of the output of a process by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. We identify waste, value stream refinement and work directly with lean consultants. Since adopting Lean Manufacturing we are disciplined in fast response times for daily communications and fast resolution to issues as they arise.

BENEFITS

- Decreased lead times

- Reduced inventory levels

- Increased product quality

- Overall supply chain performance

Bright Bars

Special Steel, Carbon Steel, Alloy Steel, Profiles.

Heat-Treated Black Bars

Alloy Steel, Special Steel, Read More

Innconel, Duplex & Super Duplex, Hastelloy.

Spring Washers

DIN 127 type B flat & DIN 7980 square type.

Threaded Bars

ASTM A193 Grade B7 , B8-class 2, B8M- Class 2, L7.

Heavy Hex Nuts

ANSI B18.2.2 Double Chamfered (Plain) A194 2H Read More

Heavy Hex Nuts, Black Finish Duly Heat Treated. ASTM A193 Grade B7 threaded Bars with Heat Treatment- Black Finish

OUR SERVICES

Vora Group is an ISO certified heat treating specialist. Heat treatment uses extreme cold and hot temperatures to create a specific amount of hardening or softening of a material. The industries we serve include Aerospace, High tolerance Bright bar, Custom designed specifics, Boiler and steam industry, shipping industry etc but the arena of our service doesn’t stop here & continues to facilitates many more wide and diversified work in Metal Industries. Our services include the below mentioned processes.

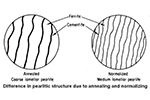

Full Annealing

A heat treatment process in which metal is heated to and then held at a sitable temperature

Read More

Tempering

A heat treatment process in which the steel is heated to a temperature below the transformation range

Read More

Cryogenic

A hardening process that cools the material to extremely low temperatures using liquid nitrogen

Read More

Sub Zero Treatment

Sub-zero treatment is carried out in order to complete the transformation

Read More

Stress Relieve / PWHT

Process of heating metal to a suitable

Read More

Solution Annealing

The process of solution annealing is typically applied to stainless steels and high

Read More

shot_blasting

Shotblasting is a method used to clean, strengthen (peen) or polish metal.

Read More

Straigtening

Straightening is a necessary step in the heat treating process of many components

Read More

Sub-Critical Annealing

Many material that under go deep draws and severe

Read More

Spheroidizing

Spheroidizing of high carbon steel is a method of prolonged heating at a temperature

Read More

Isothermal Annealing / Austempering

When applied to ferrous materials,

Read More

Vaccum Heat Treatment

Our vacuum heat treatment services are one of the best

Read More

Vaccum Annealing

Vacuum annealing (also known as bright anneal) is used to reduce internal

Read More

Vaccum Brazing

A metal joining process in which two base metals are joined together by heating

Read More

Quenching Heat Treatment (Hardening)

Our quenching heat treatments will

Read More

Precipitation Hardening

Heat treatment process in which precipitation of a constituent from

Read More

Normalizing / Normalize Hardening

Heating alloy above the

Read More

Water Quenching

It is optimum for forgings & other equipments to receive proper water quench

Read More

Oil Quenching

Oil quenching is a common method for hardening alloy steel. It’s ideal for achieving the required

Read More

Polymer Quenching

Polymer quenching provides a hardening heat treatment for steel. Polymer quenching can be utilized

Read More

Case Hardening / Carburizing

Case hardening is a process that is used to harden the outer layer of

Read More

Induction Hardening

Induction hardening is a form of heat treatment in which a metal

Read More

Aging

Aging is the treatment of a metal alloy at elevated temperatures so as to accelerate

Read MoreREASONS THAT MAKE US BENCHMARK FOR OTHERS

- High volume, low cost processing, stringent quality

- Each and every time, your parts are consistent in quality.

- A preferred supplier for many Tier 1 and OEM companies.

- Tremendous expedite response for urgent processing needs.

- Total Group capacity of 12000 tonnes per month of heat treatment.

- All heat-treatment activities under one roof with ultra modern facilities and an unparallel infrastructure to support the same.

- Bars upto length 6.5mtr can be Hardened Tempered and Solution Annealed

- Water/ Oil/ UPVC Polymer quenching available

- Water quenching tank of 90000 litres available

- Vacuum Heat-treatment, Cryogenics and Sub-zero Heat-treatment available

- Induction Hardening, Carburizing available.

- Solution Annealing of dish-ends / petals upto 5.5 mtr in width

- Bespoke material handling capabilities.

- Unambiguous control over quality.

- Quick Delivery & dependability.

- Uniformity to specs & related customer needs.

- Wide ranges of Steel Grades are processed with required properties

- Skilled and professionally trained manpower to rely upon

INDUSTRIES SERVED BY US

AEROSPACE

DEFENSE

AUTOMOTIVE

FASTENERS

INDUSTRIAL

HEAVY EQUIPMENT

TOOL AND DIE

RAIL

Forging Industries

Investment Casting

Machined Parts

Aluminium Heat

INSPECTION AGENCIES SERVED

BARC

NPCL

BVIS

TUV

IRS

ISRO

L&T

Lloyds

SGS

Godrej & Boyce

Contact Details

- Phone: 022-2927-1899 / 5018 / 1917

- info@vgiindia.com

- C-213, 2nd floor, Synthofine Estate, Opp. Virwani industrial Estate, Off Aarey Road, Goregoan (E), Mumbai – 400 063