-

Bringing Life To MetalSpecialist in Precision Controlled Heat TreatmentKnow More

Bringing Life To MetalSpecialist in Precision Controlled Heat TreatmentKnow More -

Extrusion SimplifiedBESPOKE SPECIAL STEEL PROFILES, BRIGHT BARS, FASTENERS MANUFACTURER AND DISTRIBUTORKnow More

Extrusion SimplifiedBESPOKE SPECIAL STEEL PROFILES, BRIGHT BARS, FASTENERS MANUFACTURER AND DISTRIBUTORKnow More

Our Products / Services

Our Extensive List of Products and Services Include:

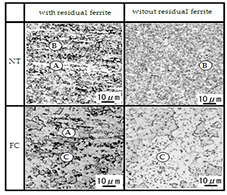

Vacuum Heat Treatment

Our vacuum Heat Treatment services are one of the best processes available.

Why Us

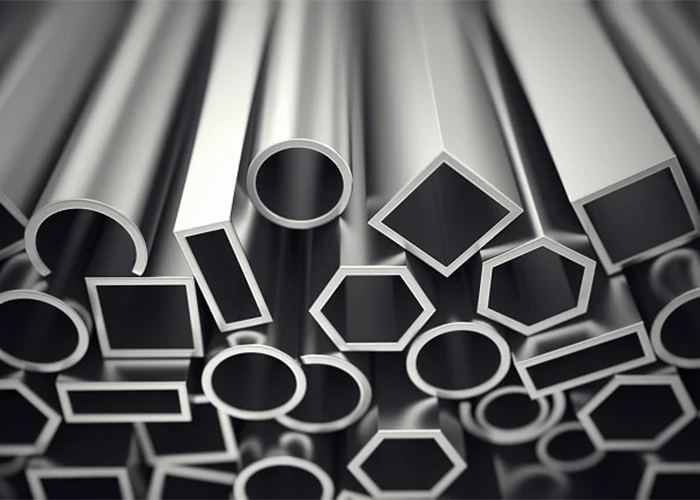

Manufacturing

- In-depth collaboration with customers to create optimized profiles for varied applications.

- Versatile shape offerings: CROSS/NOSE BAR/Mechanical Shafts.

- Multiple Bright Bar options: ROUND/FLAT/HEX/HALF ROUND/SQUARE/RECTANGLE/TRIANGLE.

- Advanced processing methods, including Cold Rolling, Cold Drawing, and Bar Straightening.

- Options for Random Mill Length Bars, Exact Length Bars, and Cut-to-Length Pieces.

- Diverse steel types: Low Carbon Steel, High Carbon Steel, Free Cutting Steel, Alloy Steel, 300 Series Stainless Steel, and 400 Series Stainless Steel.

- High precision in product dimensions and finishing.

- Reliable, on-time delivery and robust customer support.

- Compliance with quality standards to meet unique customer needs.

- Dedicated facilities to support high production volumes efficiently.

Processing

- Extensive Steel Grade processing (Ferrous + Non-Ferrous) including SS/Alloy/MS/Inconel/Duplex/Super Duplex/Monel/Cu-NI/Brass, and more.

- Rigorous quality control for optimal Heat Treatment standards.

- Quick delivery and dependable processing timelines.

- Consistent adherence to specifications and custom requirements.

- Total processing capacity of 2000 tonnes per month for heat-treatment.

- Comprehensive heat-treatment facilities centralized under one roof with modern infrastructure.

- Heat-treating capabilities for bars, pipes, and shafts up to 7 meters in length.

- Various quenching options: Water, Oil, and UPVC Polymer.

- Advanced Vacuum, Cryogenic, and Sub-zero heat-treatment, with Induction Hardening available.

- Specialized material handling and skilled, trained manpower for reliable support.

Why Us

- Cold Rolled

- Cold Drawn

- Bar Straightening

- Random Mill Length Bars

- Exact Length Bars

- Cut to Length Pieces

- Low Carbon Steel

- High Carbon Steel

- Free Cutting Steel

- Alloy Steel

- 300 Series Stainless Steel

- 400 Series Stainless Steel

- Wide ranges of Steel Grades (Ferrous+Non-Ferrous) are processed with required properties. Eg: SS/Alloy/MS/Inconel/Duplex/Super Duplex/Nimonic/Nitronic/Titanium/Precipitation Steel/Maraging Steel/Haste-alloys /HSS/HSLA/Copper nickel/aluminium steel/brass etc

- Unambiguous control over quality.

- Quick Delivery & dependability.

- Uniformity to specs & related customer needs.

- Total Group capacity of 2000 tonnes per month of Batch Heat Treatment.

- All heat-treatment activities under one roof with ultra-modern facilities and an unparallel infrastructure to support the same.

- Bars/Pipes/Shafts upto length 6.2mtr can be Hardened Tempered and Solution Annealed

- Water/ Oil/ UPVC Polymer quenching available

- Vacuum Heat-treatment, Cryogenics and Sub-zero Heat-treatment available. Induction Hardening & Carburizing available.

- Solution Annealing of dish-ends / petals upto 5.5 mtr in width and 10tons in weight. Water quenching tank of 100,000 litres available

- Atmospheric heating in batch furnaces also available

- Bespoke material handling capabilities.

- Skilled and professionally trained manpower to rely upon

- Shapes: Rounds/Flat/Hex/Square/Plates/Sheets/Wire Rods/Forgings/Pipes/Circles/Finished- Components/Elbows/Bellows/Petals/Valves/Fittings/Flanges/Rings/Castings/Dish-Ends/Fabricated Jobs/Powder Heating