Vora Group has embraced Lean Six Sigma methodology as an integral part of our business model. We seek to improve the quality of the output of a process by identifying and removing the causes of defects and minimizing variability in manufacturing and business processes. We identify waste, value stream refinement and work directly with lean consultants. Since adopting Lean Manufacturing, we maintain prompt response times for daily communications and quickly resolve issues as they arise.

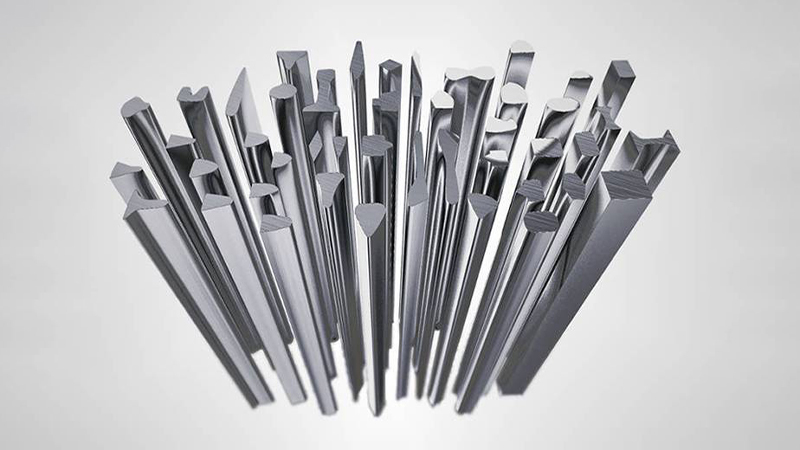

We Make The Profile You Need

Vora Industries is a manufacturer of Precision Cold Rolled & Cold Drawn Steel profiles, Mechanical Engineered shafts, ERW & Seamless tubes & HRAP wire rods in stainless steel.

Profiles can be made in wide variety of alloys that include carbon steel, free cutting steel, alloy steel, stainless steel, nickel alloys, high temp alloys.

Along with Cold drawn profiles & HRAP Coils we are also manufacturer of Bright Bars, Threaded Bars and Spring Washers.

Bright Bars: Hex/ Half Round/Square/Flat/Rounds

- We manufacture Bright Bars in Mild Steel, Carbon Steel, Alloy Steel, Stainless Steel, Special Steel and Free-Cutting Steel in all grades and specification with required tolerance having different Sizes in Round, Square, Hex, Flat and Counters and other required Profiles.

- We also supply material & Bright Bars required for Fastener Industries such as SAE 4140, SAE 8620, EN1A(L) and (NL), MS, EN9, EN8, SAE 52100 etc. and Stainless-Steel grades such as 304, 304 L, 316, 316 L, 410, 420, 431 etc to many Fastener Industries all over India and have earn good patronage by supplying quality products.

- We also supply Hardened Tempered Black bars in Alloy Steel, Special Steel, Inconel, Duplex, Super Duplex & Hastelloy.

- We are producing SAE 4140 Hardened, Tempered, Peeled, and Ground Bar for length up to 6 meters.

- In addition to above, we can supply make to order requirement of material of any grade, size & specification.

Highlights:

We develop our profiles in close collaboration with our customers to produce the best solutions for a wide variety of applications

- Cold Rolled

- Cold Drawn

- Bar Straightening

- Random Mill Length Bars

- Exact Length Bars

- Cut to Length Pieces

- Low Carbon Steel

- High Carbon Steel

- Free Cutting Steel

- Alloy Steel

- 300 Series Stainless Steel

- 400 Series Stainless Steel

Heat-Treatment:

- Wide ranges of Steel Grades (Ferrous+Non-Ferrous) are processed with required properties

- Stainless Steel/Alloy Steel/Mild Steel/Inconel/Duplex/Super Duplex/Nimonic/Nitronic/Titanium/Precipitation Steel/Maraging Steel/Haste-alloys /HSS/HSLA/Copper nikel/aluminium steel/brass etc

- Unambiguous control over quality.

- Quick Delivery & dependability.

- Uniformity to specs & related customer needs.

- Total Group capacity of 2000 tonnes per month of Batch Heat Treatment.

- All heat-treatment activities under one roof with ultra-modern facilities and an unparallel infrastructure to support the same.

- Bars/Pipes upto length 7mtr can be Hardened Tempered and Solution Annealed

- Water/ Oil/ UPVC Polymer quenching available

- Vacuum Heat-treatment, Cryogenics and Sub-zero Heat-treatment available. Induction Hardening available.

- Solution Annealing of dish-ends / petals upto 5.5 mtr in width and 10tons in weight. Water quenching tank of 100,000 litres available

- Atmospheric heating in batch furnaces also available

- Bespoke material handling capabilities.

- Skilled and professionally trained manpower to rely upon

- Shapes: Rounds/Flat/Hex/Square/Plates/Sheets/Wire Rods/Forgings/Pipes/Circles/Finished-Components/Elbows/Bellows/Petals/Valves/Fittings/Flanges/Rings/Castings/Dish-Ends/Fabricated Jobs/Powder Heating

- Wide ranges of Steel Grades (Ferrous+Non-Ferrous) are processed with required properties

- Stainless Steel/Alloy Steel/Mild Steel/Inconel/Duplex/Super Duplex/Nimonic/Nitronic/Titanium/Precipitation Steel/Maraging Steel/Haste-alloys /HSS/HSLA/Copper nikel/aluminium steel/brass etc

- Unambiguous control over quality.

- Quick Delivery & dependability.

- Uniformity to specs & related customer needs.

- Total Group capacity of 2000 tonnes per month of Batch Heat Treatment.

- All heat-treatment activities under one roof with ultra-modern facilities and an unparallel infrastructure to support the same.

- Bars/Pipes upto length 7mtr can be Hardened Tempered and Solution Annealed

- Water/ Oil/ UPVC Polymer quenching available

- Vacuum Heat-treatment, Cryogenics and Sub-zero Heat-treatment available. Induction Hardening available.

- Solution Annealing of dish-ends / petals upto 5.5 mtr in width and 10tons in weight. Water quenching tank of 100,000 litres available

- Atmospheric heating in batch furnaces also available

- Bespoke material handling capabilities.

- Skilled and professionally trained manpower to rely upon

- Shapes: Rounds/Flat/Hex/Square/Plates/Sheets/Wire Rods/Forgings/Pipes/Circles/Finished-Components/Elbows/Bellows/Petals/Valves/Fittings/Flanges/Rings/Castings/Dish-Ends/Fabricated Jobs/Powder Heating