Batch Heat Treatment

Vora Group is an ISO certified heat-treating specialist. The industries we serve include Aerospace, High tolerance bright bar, Custom designed specifics, Boiler and Steam industry, Shipping industry, and others. The arena of our service doesn’t stop here & continues to facilitate much wider and diversified work in Metal Industries. Our services include the below-mentioned processes.

A batch heat treatment process is used in which metal is heated and held at a suitable temperature, then slowly cooled at a suitable range This process is used to soften metals and increase the malleability.

A Batch Heat Treatment process in which the steel is heated to a temperature below the transformation range, held for a suitable time, and then cooled. The result is decreased hardness and increased toughness.

Process of heating metal to a suitable temperature and then holding that temperature for a certain amount of time to reduce residual stresses. The part is then slowly cooled to further minimize the risk of developing new residual stresses.

The process of solution annealing is typically applied to stainless steels and high nickel alloys for heat resistant and corrosion resistant applications. These are generally high temperature processes requiring rapid quenching.

Many material that under go deep draws and severe forming operations exhibit high cold work hardnesses that prevent further drawing or stamping operations. Sub-critical annealing is an ideal way to remove these stresses to allow subsequent forming operations. The temperature ranges for this process typically range from 1250F to 1400F.

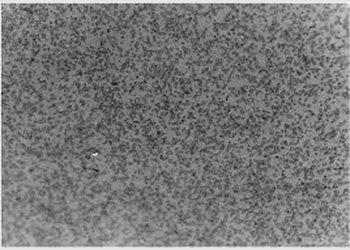

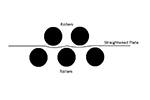

Straightening is a necessary step in the heat treating process of many components. Due to mechanical deformation and manifestation of stresses during heating and quenching, parts often warp to beyond acceptable tolerances with respect to straightness and flatness. Therefore straightening operations become a necessity to bring the parts back within acceptable ranges

Our quenching Batch Heat Treatments will result in a guaranteed improvement of the mechanical properties of your products, as well as an increase in their level of toughness—making these items more durable. Steel parts often require a specific form of Batch Heat Treatment to obtain an increase in hardness and strength. And at VG, we are highly-trained in these processes.

During a quenching Batch Heat Treatment, the material is heated up to suitable temperatures and then quenched in oil to fully harden, varying on the kind of steel being worked on. Items that go through this are then aged, tempered or stress relieved to achieve the desired stability.

Batch Heat Treatment process in which precipitation of a constituent from a super saturated solid saturation causes hardening in metals.

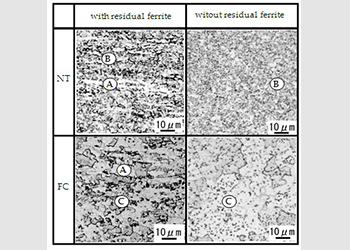

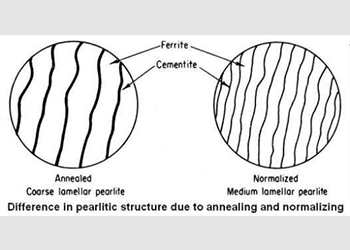

Heating alloy above the transformation range, holding at this temperature, then cooling in air to a temperature below transformation range. This results in stress relieving, increased strength, and increased hardness.

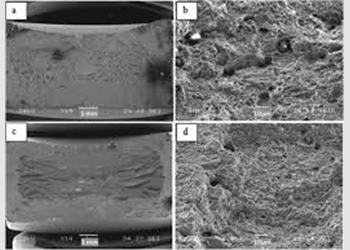

The process is employed also on forged products to homogenize the grain structure, improve machinability, and improve response to subsequent heat treating processes

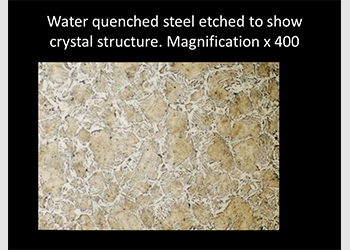

It is optimum for forgings & other equipments to receive proper water quench hardening in order to avoid undesirable microstructural components, which can lead to low hardnesses, mechanical properties, and failures during service.

VG’S water quenching capabilities achieve both the hardness & mechanical requirements needed on low alloy steel forgings.Our water quenching system has several cooling towers on it to ensure the quench media is as cool as possible for repetive results in our batch quenching operations.

Oil quenching is a common method for hardening alloy steel. It’s ideal for achieving the required strength and hardness properties in many alloys. When you oil quench steel there’s also less risk of cracking compared to water quenching or polymer quenching. When we oil quench steel we start by fully austenitizing the steel in the temperature range of 1500°F – 1650°F, depending on the steel grade. It’s held at this temperature for a time proportionate with the part cross-section. The initial austenitizing is typically done in a carbon-controlled atmosphere. This atmosphere prevents excessive scale formation on the surface.Once soaked at the austenitizing temperature for the appropriate amount of time, the forgings are quenched in agitated oil. This produces a fully hardened martensitic microstructure, the depth of which is dependent on the alloy grade and section thickness.At this point, the parts are tempered down to the specified hardness range for improved toughness.

Polymer quenching provides a hardening Batch Heat Treatment for steel. Polymer quenching can be utilized with excellent results on plain carbon & alloy steels that require superior depth of hardness & uniform, repeatable mechanical properties.

It is particularly useful in applications that require high impact values in both longitudinal and transverse directions.

When properly applied, polymer quenching yields superior results as compared to oil quenching; however, all quench variables must be controlled to achieve repeatable results.

Polymer quenching is particularly useful for quenching high integrity alloy steel forgings that require impact testing.

Heavy section AISI 4140 forgings that need good depth of hardness can be a challenge when oil quenched. Our polymer quenching hardening Batch Heat Treatment can be the solution for jobs that do not respond properly to oil quenching.

Shot Blasting

Shot Blasting is a method used to clean, strengthen (peen) or polish metal. Shot blasting is used in almost every industry that uses metal, including aerospace, automotive, construction, foundry, shipbuilding, rail, and many others. There are two technologies used: wheelblasting or airblasting.

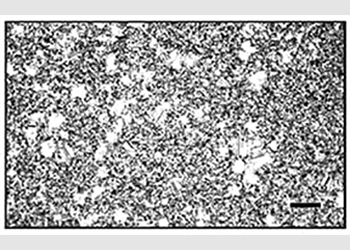

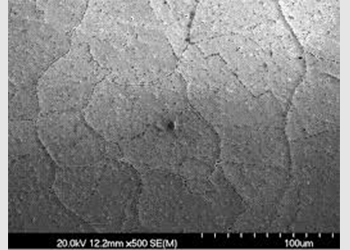

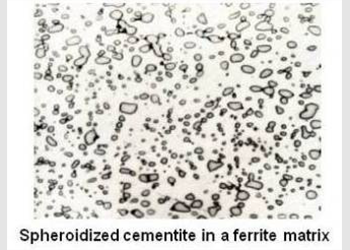

Spheroidizing

Spheroidizing of high carbon steel is a method of prolonged heating at a temperature below the eutectoid temperature. By heating at this temperature pearlite, which is the lowest energy arrangement of steel, gets converted to ferrite and cementite.