Vacuum Heat Treatment

Vaccum

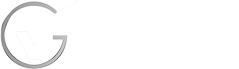

Our vacuum Batch Heat Treatment services are one of the best processes available. Vacuum heat treating is when metal parts are exposed to temperatures of heat in order to change their properties. A hard or partial pressure vacuum austenitizes steel parts. This protects the surface of the parts during this operation. These processes shorten carburizing cycles, reduce overall processing time, and lower gas consumption. There are numerous treatments involving our vacuum processes that we use. These treatments achieve higher strength, better wear resistance and improve the corrosion behavior of the subjected material. At VG, our treatments offer the best protection against oxidation while remaining extremely cost-efficient.

Vacuum Harden-Nitrogen Quench

Vacuum hardening utilizes a heating operation in the absence of oxygen which prevents oxidation and decarburization. With the use of gas quenching, distortion is reduced when compared to oil.

Vacuum Anneal

Vacuum annealing (also known as bright anneal) is used to reduce internal stress and improve workability. It can also be applied to finished parts without effecting the parts appearance.

Vacuum Braze

A metal joining process in which two base metals are joined together by heating to a suitable temperature and using a filler metal. This takes place in a vacuum furnace that uses low atmospheric pressures instead of a protective gas atmosphere.

Cryogenic

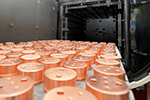

A hardening process that cools the material to extremely low temperatures using liquid nitrogen, making sure no austenite is retained during quenching. This helps to increase wear resistance.

Cryogenic Treatment is primarily used to transform retained austenite from a hardening process into martensite. The treatment is sometimes used in shrink-fit operations, for mating components with high interference, and may also be used for stress-relief as well as to promote dimensional stability before sensitive grinding operations.

Case Hardening

Case hardening is a process that is used to harden the outer layer of case hardening steel while maintaining a soft inner metal core. The case hardening process uses case hardening compounds for the carbon addition. Steel case hardening depth depends upon the application of case hardening depth.

Carburizing, also referred to as Case Hardening, is a Batch Heat Treatment process that produces a surface which is resistant to wear, while maintaining toughness and strength of the core. This treatment is applied to low carbon steel parts after machining, as well as high alloy steel bearings, gears, and other components.

Induction Hardening

Induction hardening is a form of Batch Heat Treatment in which a metal part is heated by induction heating and then quenched. The quenched metal undergoes a martensitic transformation, increasing the hardness and brittleness of the part. Induction hardening is used to selectively harden areas of a part or assembly without affecting the properties of the part as a whole.